Via jumps

- Via jumps are necessary if a transmission line needs to switch lanes.

- In order to avoid signal reflections the characteristic impedance of the transmission line needs to remain constant when traversing from between layers through a via.

Coaxial via

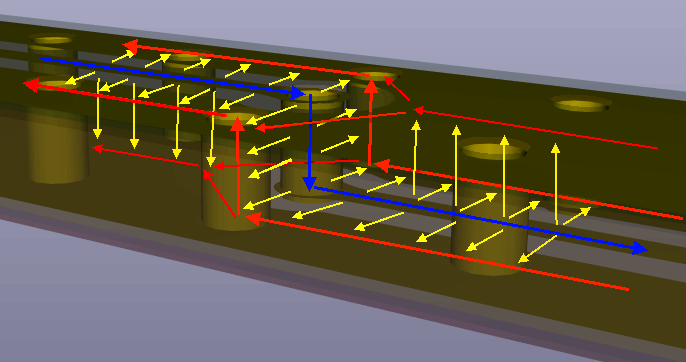

Diagram 6. Via jump with current path (red/blue) and E-field (yellow)

- If there are no nearby grounding vias then a distant current return path is used which results in a significant impedance mismatch.

- Instead we add nearby grounding vias to provide a current return path.

- This type of via structure is called a coaxial via.

- The following parameters are important when trying to control the impedance of a coaxial via:

- Distance of ground vias from signal via.

- Number of ground vias around the signal via.

- Hole size of the ground via and signal via.

- Dielectric material used to fill the vias.

Teardrop taper

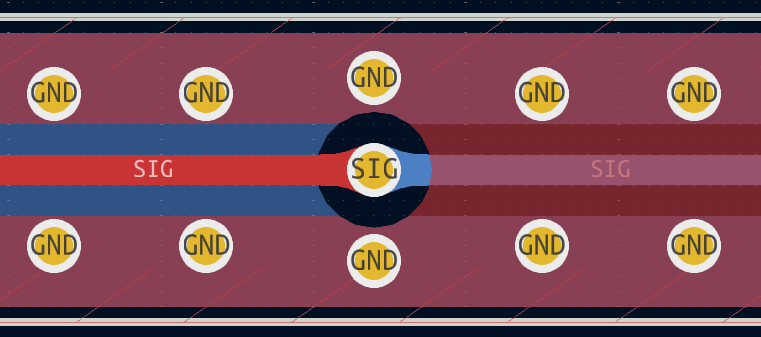

Diagram 7. Via jump design with teardrop taper

- When a signal trace goes through a via there is an impedance discontinuity especially if the trace width and via diameter are different.

- Adjusting the following can reduce the impedance discontinuity:

- Adding a teardrop taper to match trace width to via diameter.

- Adjusting the via annular diameter.

- Adjusting the via hole size.

Determining parameters

- There is no closed form equation for the impedance of a coaxial via with a teardrop taper.

- This means running a parametric search through a simulation to determine the optimal parameter values.

- Very difficult to do given the number of parameters for the coaxial via and teardrop taper which all impact performance.

- Refer to this section about simulating circuits with openEMS.

Via stubs

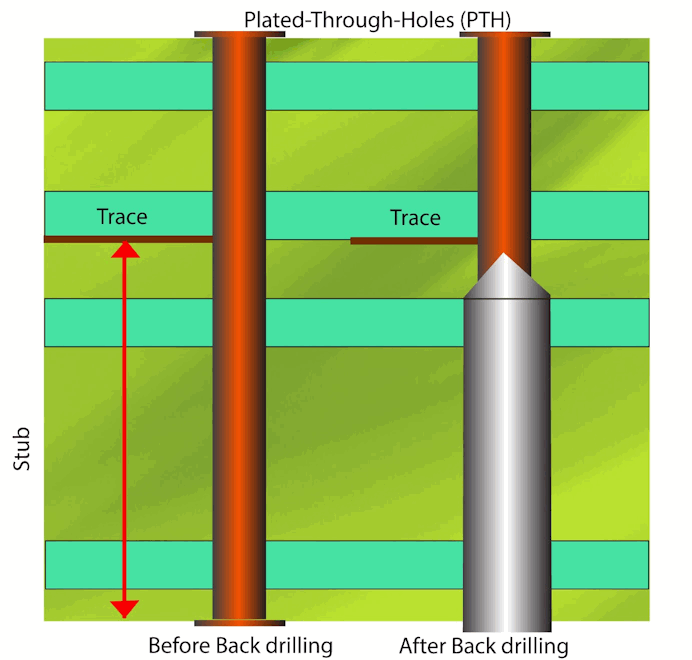

Diagram 8. Via stub back drilling

(source)

- If via jump isn’t between the top and bottom layers then there will be a stub segment in the via.

- This will have the most signficant impact at the following frequency:

\[ f_0 = \frac{c}{4 \sqrt{\epsilon_r} \times d_{stub}} \]

- Actual performance degradation happens well before this frequency.

- By decreasing \( d_{stub} \) we can increase \( f_0 \) well past our maximum design frequency and avoid problems.

- If the via stub is sufficiently short then it will not have a noticeable impact on signal integrity below our maximum design frequency.

Buried, blind and through hole vias

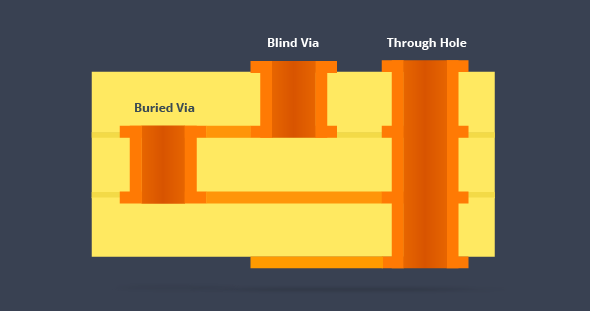

Diagram 9. Buried, blind and through hole vias

(source)

- Buried and blind vias can be used to avoid via stubs.

- These types of vias can be manufactured using a technique called backdrilling.

- However JLCPCB only supports through hole vias.