Skin effect

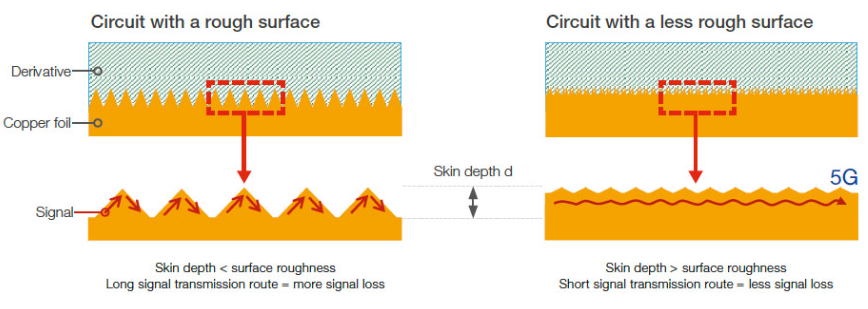

Diagram 10. Visualisation of skin effect on rough conductive surfaces

(source)

- Skin effect is when the signal current is expelled to the surface of the conductor at high frequencies.

- With a rough copper finish, skin effect can result in higher trace impedance which can result in:

- Signal loss through resistive losses.

- Impedance mismatch and signal reflections.

Increasing trace width

- Use wider tranmission line signal traces to improve impedance and therefore signal integrity at higher frequencies.

- Comes at the cost of worse impedance matching at lower frequencies.

- Signal losses generally occur at higher frequencies (via jumps, tapered transitions, skin effect, insertion loss, dielectric loss).

- Therefore to achieve best performance over the entire bandwidth we should increase transmission line width to mitigate skin effect at higher frequencies.

Copper finish

- PCB manufacturers have a variety of copper foil types to use if you need a smoother surface to avoid skin effect.

| Type of copper foil | Description | Roughness |

|---|---|---|

| Electrodeposited | Has a rougher surface on one side of the copper foil | Highest (above 1 um) |

| Reverse treated | Uses a surface treatment to reduce roughness | Moderate (0.5 um to 1.5 um) |

| Rolled-annealed | Has a smoother, denser surface from a rolling process | Low (0.25 to 0.5 um) |

| Ultra-low profile | Additional treatments are used to reduce roughness | Lowest (comparable to rolled annealed, but can be less than 0.3 um) |

- Unfortunately JLCPCB doesn’t allow you to select the type of copper foil.